Factory wholesale Tungsten Carbide Components For Liquid Dispensing Machine - Copper Tungsten – De-Shin

Product Detail

Product Tags

Related Video

Feedback (2)

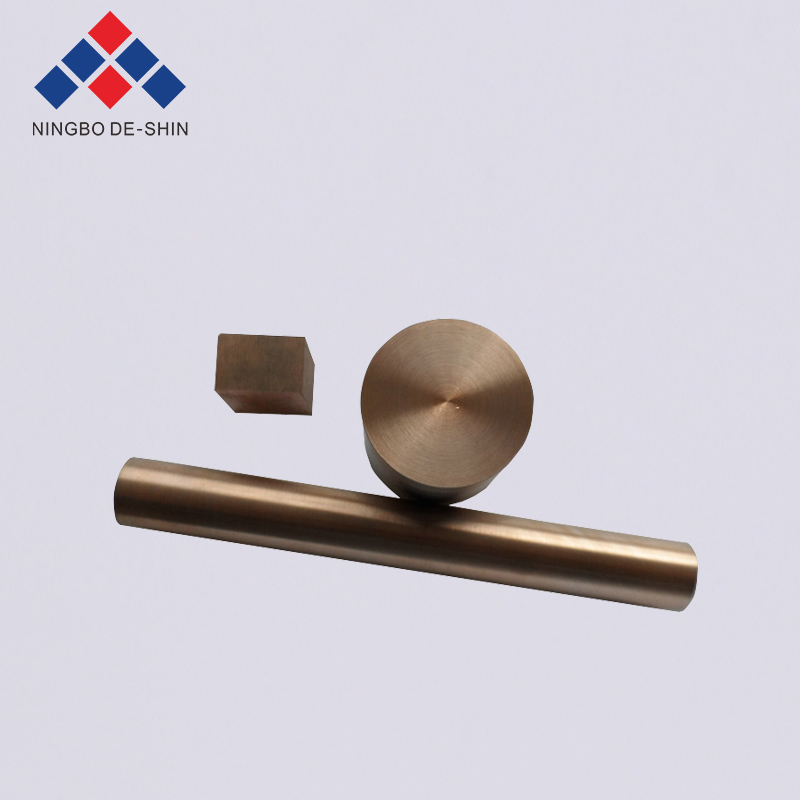

Factory wholesale Tungsten Carbide Components For Liquid Dispensing Machine - Copper Tungsten – De-Shin Detail:

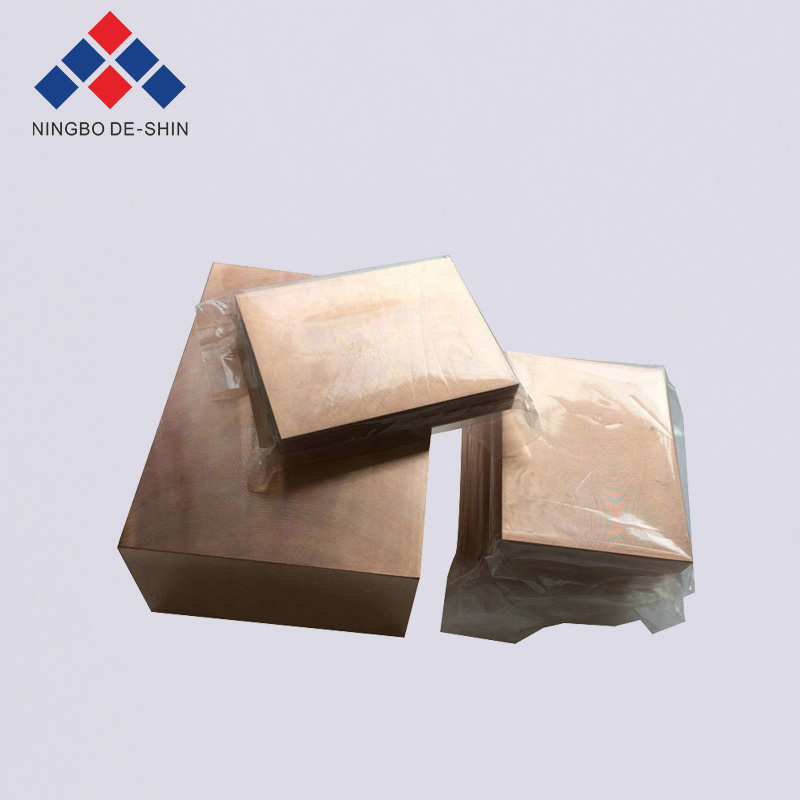

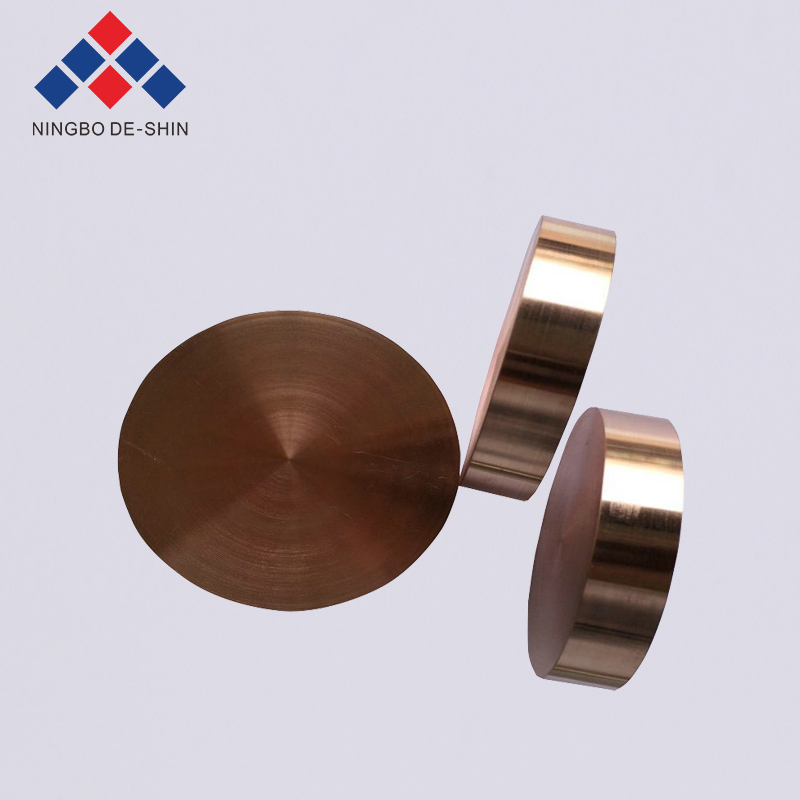

Ningbo De-Shin offers a full range of copper tungsten(6~50wt.% Cu) for different industrial application fields. It takes the advanced vacuum infiltration process and all products meet the criterion of GB/T 8320-2003, ASTM B 702-93(Reapproved 2004). Copper tungsten is pseudo-alloy and it holds the wear resistance capability of tungsten and high electrical conductivity of copper.

Production process: powder mix –> press –> sintering –> vacuum infiltration –> machining –> QC. All this production process is strictly controlled by QC to ensure best quality performance.

Advantages:

1. High arc resistance combined with good electrical conductivity.

2. High thermal conductivity.

3. Low thermal expansion.

Applications:

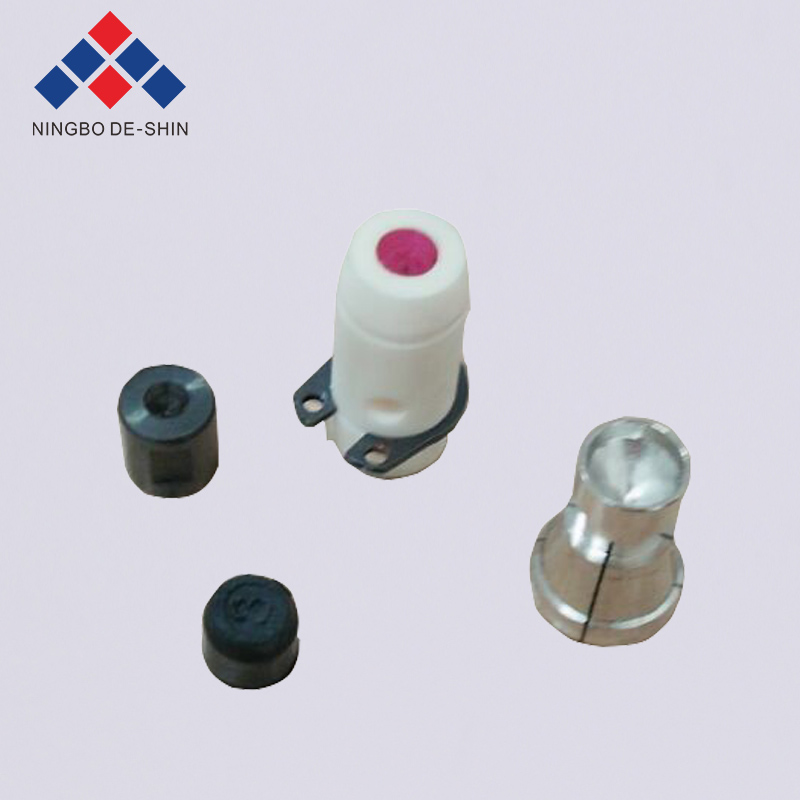

1. Arcing contacts and vaccum contacts in high and medium voltage breakers or vaccum interruptors.

2. Electrodes in electric spark erosion cutting machines.

3. Product Demo! Heat sinks as passive cooling elements of electronic devices and Electronic packaging materials.

4. Electrodes for resistance welding.

Stock size:

Copper tungsten rod: diameter≥0.5mm; length≤300mm.

Copper tungsten plate: thickness≥1.0mm; length & width≤300mm.

| grade | Chemical Composition (wt%) | Density | Hardness | Resistivity | IACS | Bending Strength | ||

| Cu | Total Impurities≤ | W | g/cm3 ≥ | HB Kgf/mm2 ≥ | μΩ.cm ≤ | % ≥ | MPa ≥ | |

| W50/Cu50 | 50±2.0 | 0.5 | Balance | 11.85 | 115 | 3.2 | 54 | – |

| W55/Cu45 | 45±2.0 | 0.5 | Balance | 12.30 | 125 | 3.5 | 49 | – |

| W60/Cu40 | 40±2.0 | 0.5 | Balance | 12.75 | 140 | 3.7 | 47 | – |

| W65/Cu35 | 35±2.0 | 0.5 | Balance | 13.30 | 155 | 3.9 | 44 | – |

| W70/Cu30 | 30±2.0 | 0.5 | Balance | 13.80 | 175 | 4.1 | 42 | 790 |

| W75/Cu25 | 25±2.0 | 0.5 | Balance | 14.50 | 195 | 4.5 | 38 | 885 |

| W80/Cu20 | 20±2.0 | 0.5 | Balance | 15.15 | 220 | 5.0 | 34 | 980 |

| W85/Cu15 | 15±2.0 | 0.5 | Balance | 15.90 | 240 | 5.7 | 30 | 1080 |

| W90/Cu10 | 10±2.0 | 0.5 | Balance | 16.75 | 260 | 6.5 | 27 | 1160 |

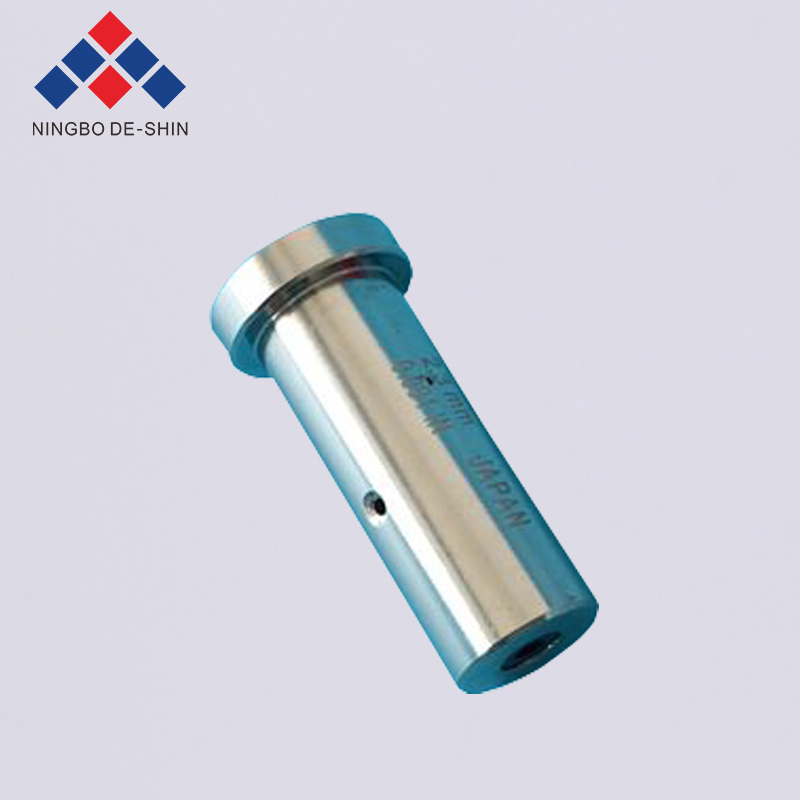

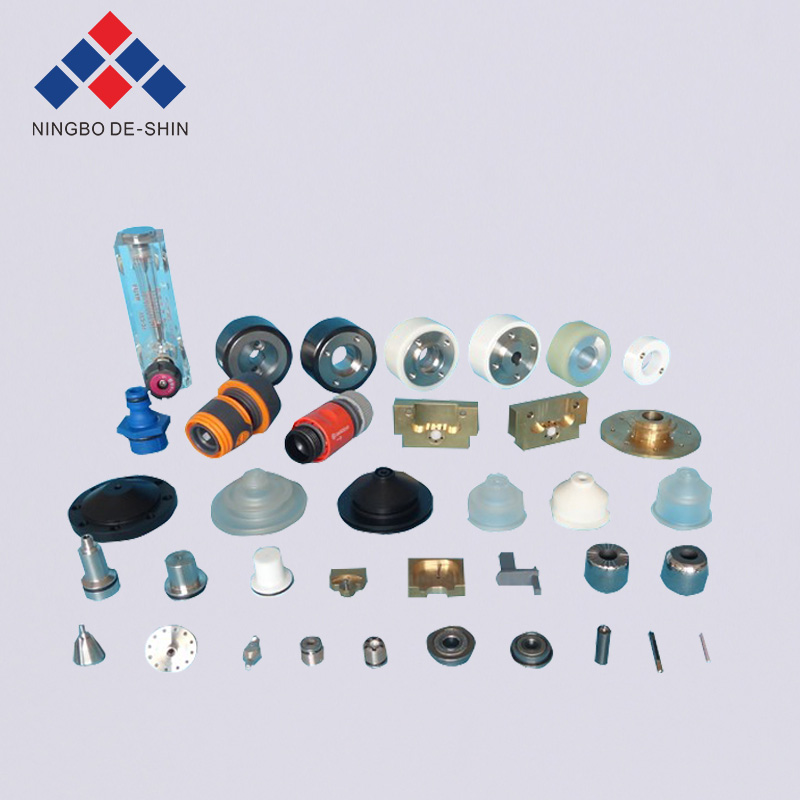

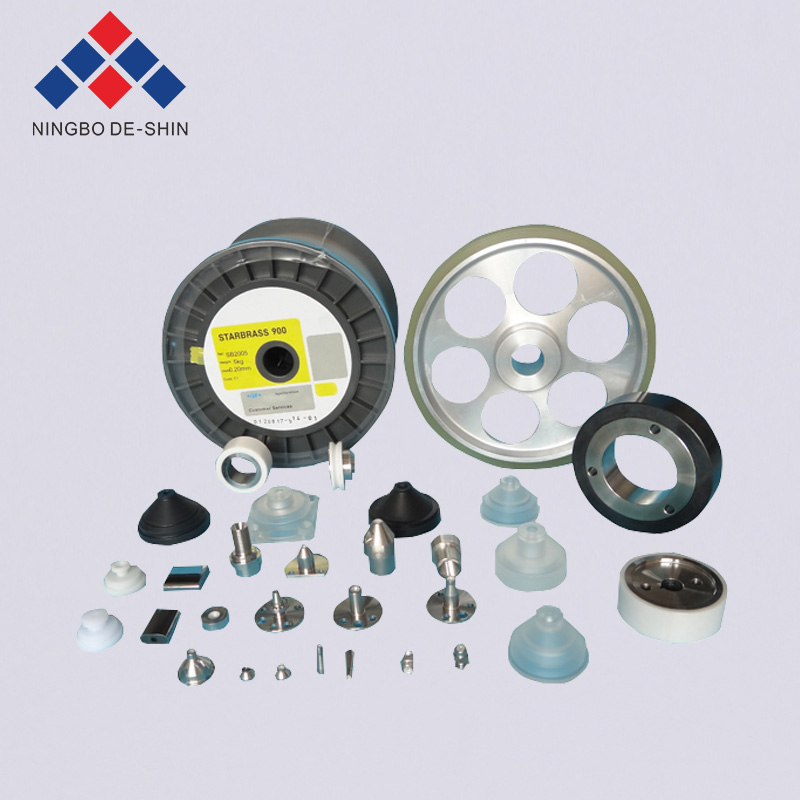

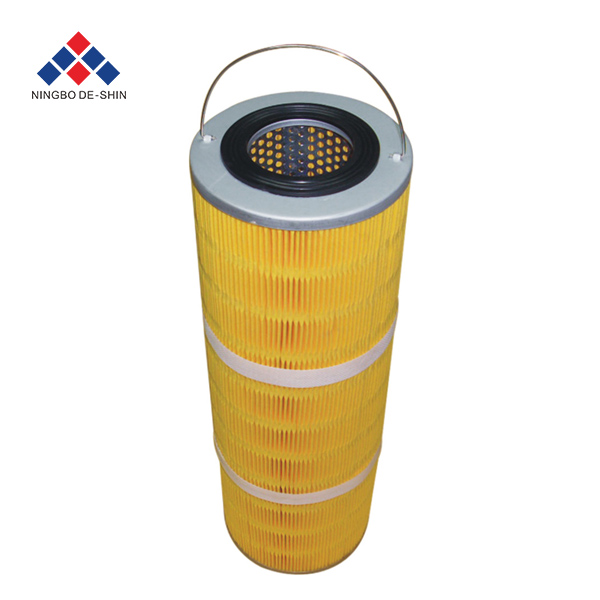

Product detail pictures:

Related Product Guide:

Wire EDM Costs

Used Wire EDM Machines

We always follow the principle "Quality Very first, Prestige Supreme". We have been fully committed to delivering our customers with competitively priced high-quality products and solutions, prompt delivery and experienced services for Factory wholesale Tungsten Carbide Components For Liquid Dispensing Machine - Copper Tungsten – De-Shin, The product will supply to all over the world, such as: Vietnam, Iran, Bolivia, Our company upholds the spirit of "innovation, harmony, team work and sharing, trails, pragmatic progress". Give us a chance and we will prove our capability. With your kind help, we believe that we can create a bright future with you together.

The enterprise has a strong capital and competitive power, product is sufficient, reliable, so we have no worries on cooperating with them.