OEM Supply Custom Metal Cnc Turning Service - Copper Tungsten – De-Shin

Product Detail

Product Tags

Related Video

Feedback (2)

OEM Supply Custom Metal Cnc Turning Service - Copper Tungsten – De-Shin Detail:

Ningbo De-Shin offers a full range of copper tungsten(6~50wt.% Cu) for different industrial application fields. It takes the advanced vacuum infiltration process and all products meet the criterion of GB/T 8320-2003, ASTM B 702-93(Reapproved 2004). Copper tungsten is pseudo-alloy and it holds the wear resistance capability of tungsten and high electrical conductivity of copper.

Production process: powder mix –> press –> sintering –> vacuum infiltration –> machining –> QC. All this production process is strictly controlled by QC to ensure best quality performance.

Advantages:

1. High arc resistance combined with good electrical conductivity.

2. High thermal conductivity.

3. Low thermal expansion.

Applications:

1. Arcing contacts and vaccum contacts in high and medium voltage breakers or vaccum interruptors.

2. Electrodes in electric spark erosion cutting machines.

3. Product Demo! Heat sinks as passive cooling elements of electronic devices and Electronic packaging materials.

4. Electrodes for resistance welding.

Stock size:

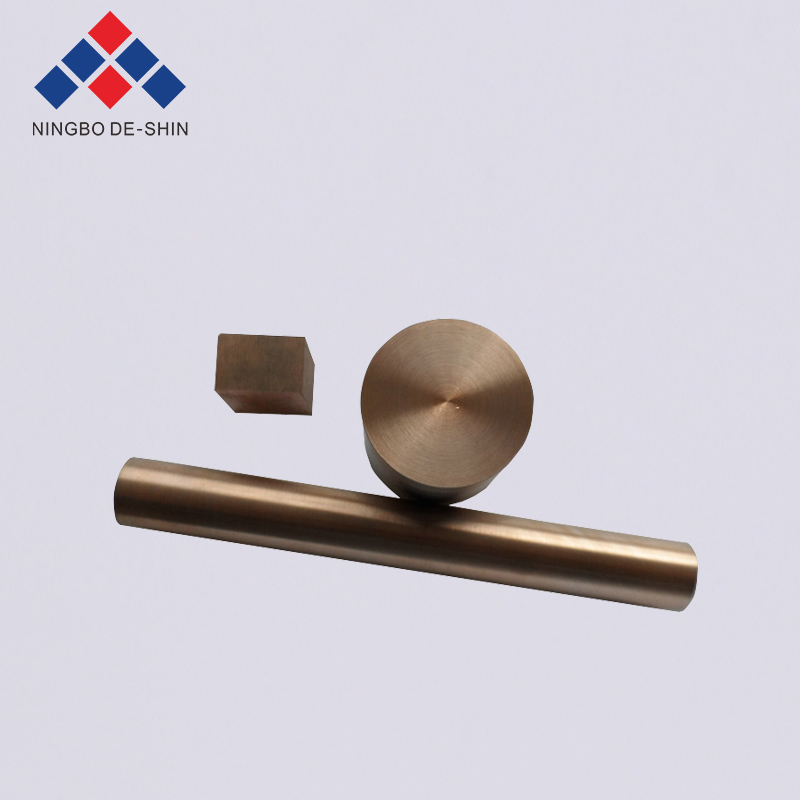

Copper tungsten rod: diameter≥0.5mm; length≤300mm.

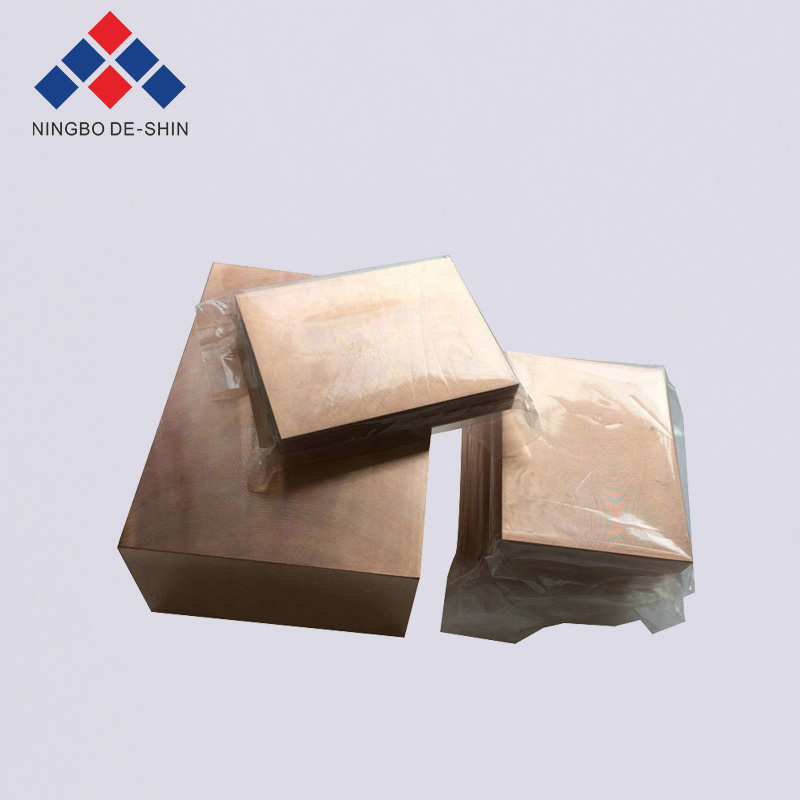

Copper tungsten plate: thickness≥1.0mm; length & width≤300mm.

| grade | Chemical Composition (wt%) | Density | Hardness | Resistivity | IACS | Bending Strength | ||

| Cu | Total Impurities≤ | W | g/cm3 ≥ | HB Kgf/mm2 ≥ | μΩ.cm ≤ | % ≥ | MPa ≥ | |

| W50/Cu50 | 50±2.0 | 0.5 | Balance | 11.85 | 115 | 3.2 | 54 | – |

| W55/Cu45 | 45±2.0 | 0.5 | Balance | 12.30 | 125 | 3.5 | 49 | – |

| W60/Cu40 | 40±2.0 | 0.5 | Balance | 12.75 | 140 | 3.7 | 47 | – |

| W65/Cu35 | 35±2.0 | 0.5 | Balance | 13.30 | 155 | 3.9 | 44 | – |

| W70/Cu30 | 30±2.0 | 0.5 | Balance | 13.80 | 175 | 4.1 | 42 | 790 |

| W75/Cu25 | 25±2.0 | 0.5 | Balance | 14.50 | 195 | 4.5 | 38 | 885 |

| W80/Cu20 | 20±2.0 | 0.5 | Balance | 15.15 | 220 | 5.0 | 34 | 980 |

| W85/Cu15 | 15±2.0 | 0.5 | Balance | 15.90 | 240 | 5.7 | 30 | 1080 |

| W90/Cu10 | 10±2.0 | 0.5 | Balance | 16.75 | 260 | 6.5 | 27 | 1160 |

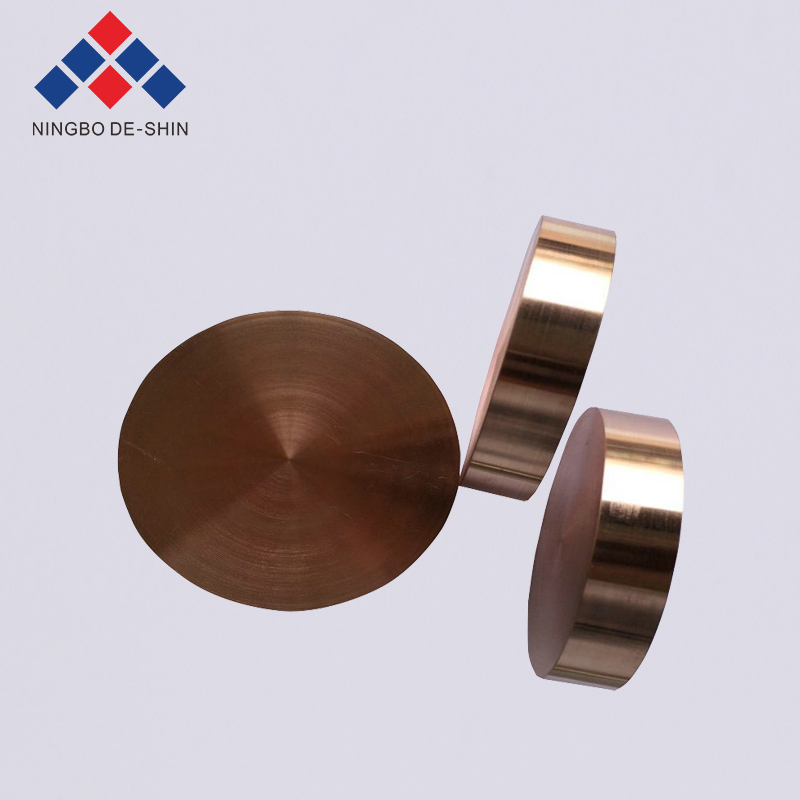

Product detail pictures:

Related Product Guide:

Wire EDM Manufacturers

Wire EDM Materials

We've got a highly efficient group to deal with inquiries from shoppers. Our purpose is "100% client fulfillment by our product high-quality, price tag & our staff service" and enjoy a superb reputation amongst clientele. With quite a few factories, we will provide a wide variety of OEM Supply Custom Metal Cnc Turning Service - Copper Tungsten – De-Shin, The product will supply to all over the world, such as: Canada, Toronto, Botswana, Our products are widely recognized and trusted by users and can meet continuously developing economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success!

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.