Top Suppliers Custom Brass Cnc Machining Parts - Copper Tungsten – De-Shin

Product Detail

Product Tags

Related Video

Feedback (2)

Top Suppliers Custom Brass Cnc Machining Parts - Copper Tungsten – De-Shin Detail:

Ningbo De-Shin offers a full range of copper tungsten(6~50wt.% Cu) for different industrial application fields. It takes the advanced vacuum infiltration process and all products meet the criterion of GB/T 8320-2003, ASTM B 702-93(Reapproved 2004). Copper tungsten is pseudo-alloy and it holds the wear resistance capability of tungsten and high electrical conductivity of copper.

Production process: powder mix –> press –> sintering –> vacuum infiltration –> machining –> QC. All this production process is strictly controlled by QC to ensure best quality performance.

Advantages:

1. High arc resistance combined with good electrical conductivity.

2. High thermal conductivity.

3. Low thermal expansion.

Applications:

1. Arcing contacts and vaccum contacts in high and medium voltage breakers or vaccum interruptors.

2. Electrodes in electric spark erosion cutting machines.

3. Product Demo! Heat sinks as passive cooling elements of electronic devices and Electronic packaging materials.

4. Electrodes for resistance welding.

Stock size:

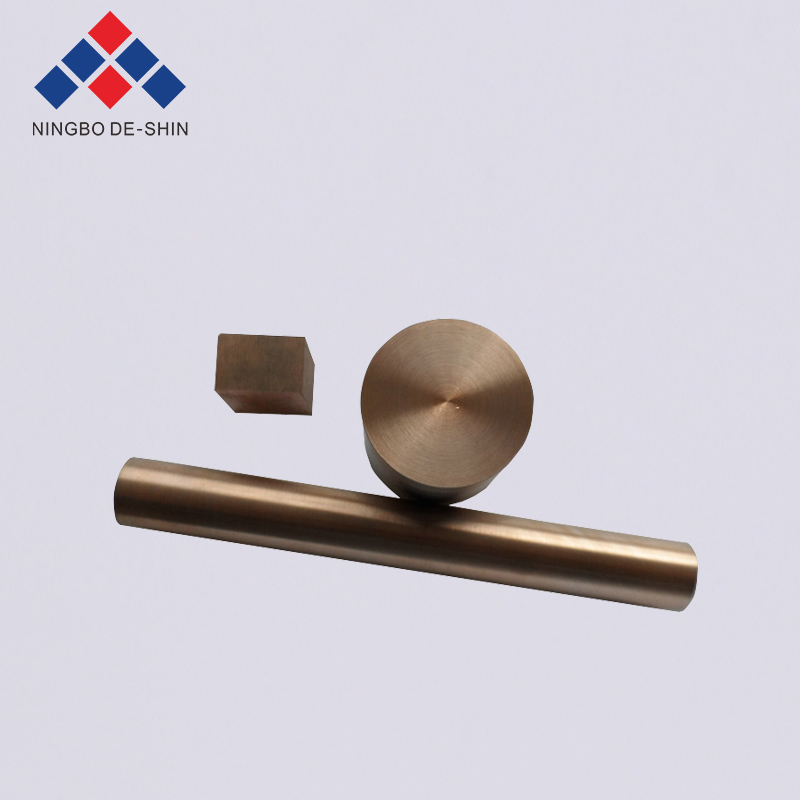

Copper tungsten rod: diameter≥0.5mm; length≤300mm.

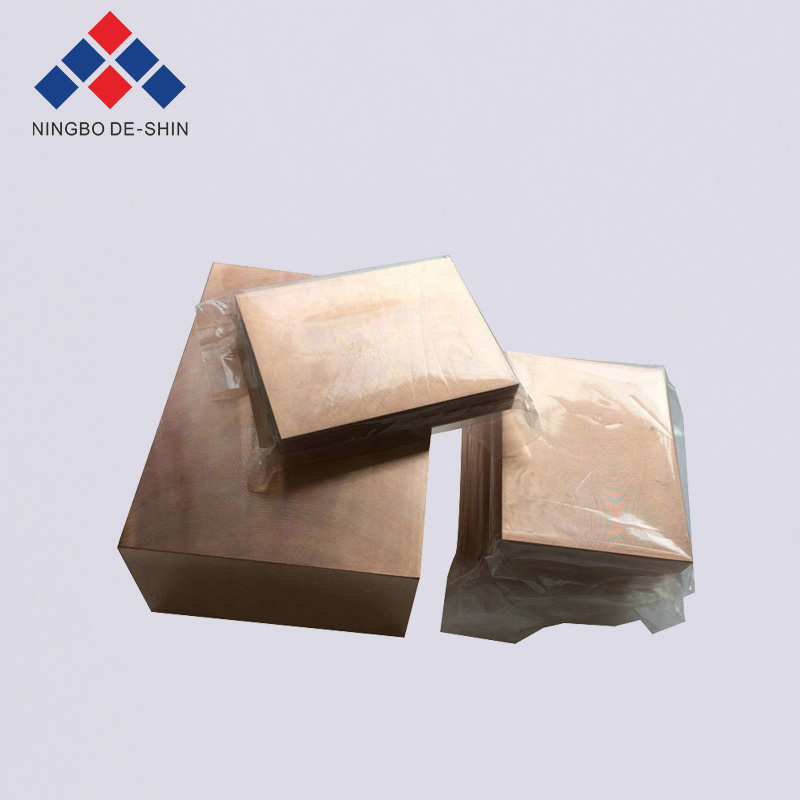

Copper tungsten plate: thickness≥1.0mm; length & width≤300mm.

| grade | Chemical Composition (wt%) | Density | Hardness | Resistivity | IACS | Bending Strength | ||

| Cu | Total Impurities≤ | W | g/cm3 ≥ | HB Kgf/mm2 ≥ | μΩ.cm ≤ | % ≥ | MPa ≥ | |

| W50/Cu50 | 50±2.0 | 0.5 | Balance | 11.85 | 115 | 3.2 | 54 | – |

| W55/Cu45 | 45±2.0 | 0.5 | Balance | 12.30 | 125 | 3.5 | 49 | – |

| W60/Cu40 | 40±2.0 | 0.5 | Balance | 12.75 | 140 | 3.7 | 47 | – |

| W65/Cu35 | 35±2.0 | 0.5 | Balance | 13.30 | 155 | 3.9 | 44 | – |

| W70/Cu30 | 30±2.0 | 0.5 | Balance | 13.80 | 175 | 4.1 | 42 | 790 |

| W75/Cu25 | 25±2.0 | 0.5 | Balance | 14.50 | 195 | 4.5 | 38 | 885 |

| W80/Cu20 | 20±2.0 | 0.5 | Balance | 15.15 | 220 | 5.0 | 34 | 980 |

| W85/Cu15 | 15±2.0 | 0.5 | Balance | 15.90 | 240 | 5.7 | 30 | 1080 |

| W90/Cu10 | 10±2.0 | 0.5 | Balance | 16.75 | 260 | 6.5 | 27 | 1160 |

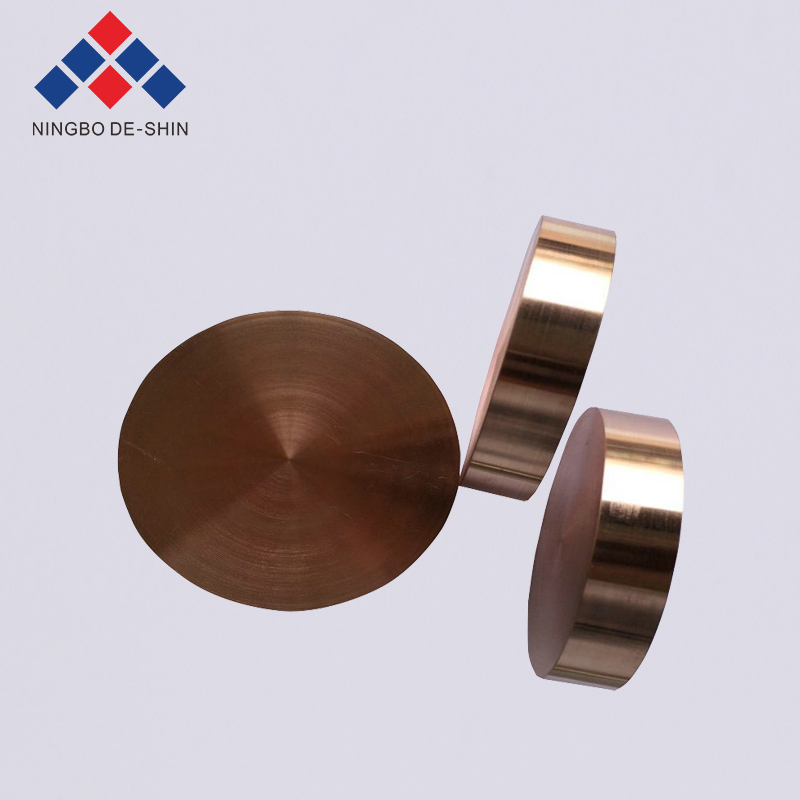

Product detail pictures:

Related Product Guide:

Advances in Wire EDM Technology

Used Wire EDM Machines

"Control the standard by the details, show the power by quality". Our firm has strived to establish a extremely efficient and stable employees crew and explored an effective excellent command method for Top Suppliers Custom Brass Cnc Machining Parts - Copper Tungsten – De-Shin, The product will supply to all over the world, such as: Nigeria, Provence, Austria, Regarding quality as survival, prestige as guarantee, innovation as motive force, development along with advanced technology, our group hopes to make progress together with you and make untiring efforts for the bright future of this industry.

In China, we have many partners, this company is the most satisfying to us, reliable quality and good credit, it is worth appreciation.